Thermal Insights

Welcome to our Thermal Insights, the place for you to learn how heat exchangers work, what they are used for, what makes them great, and how they can be used in your business. Launch into the world of air-to-air heat exchangers with the help of PRE-heat.

The Top Uses for Indirect-Fired Air Heaters

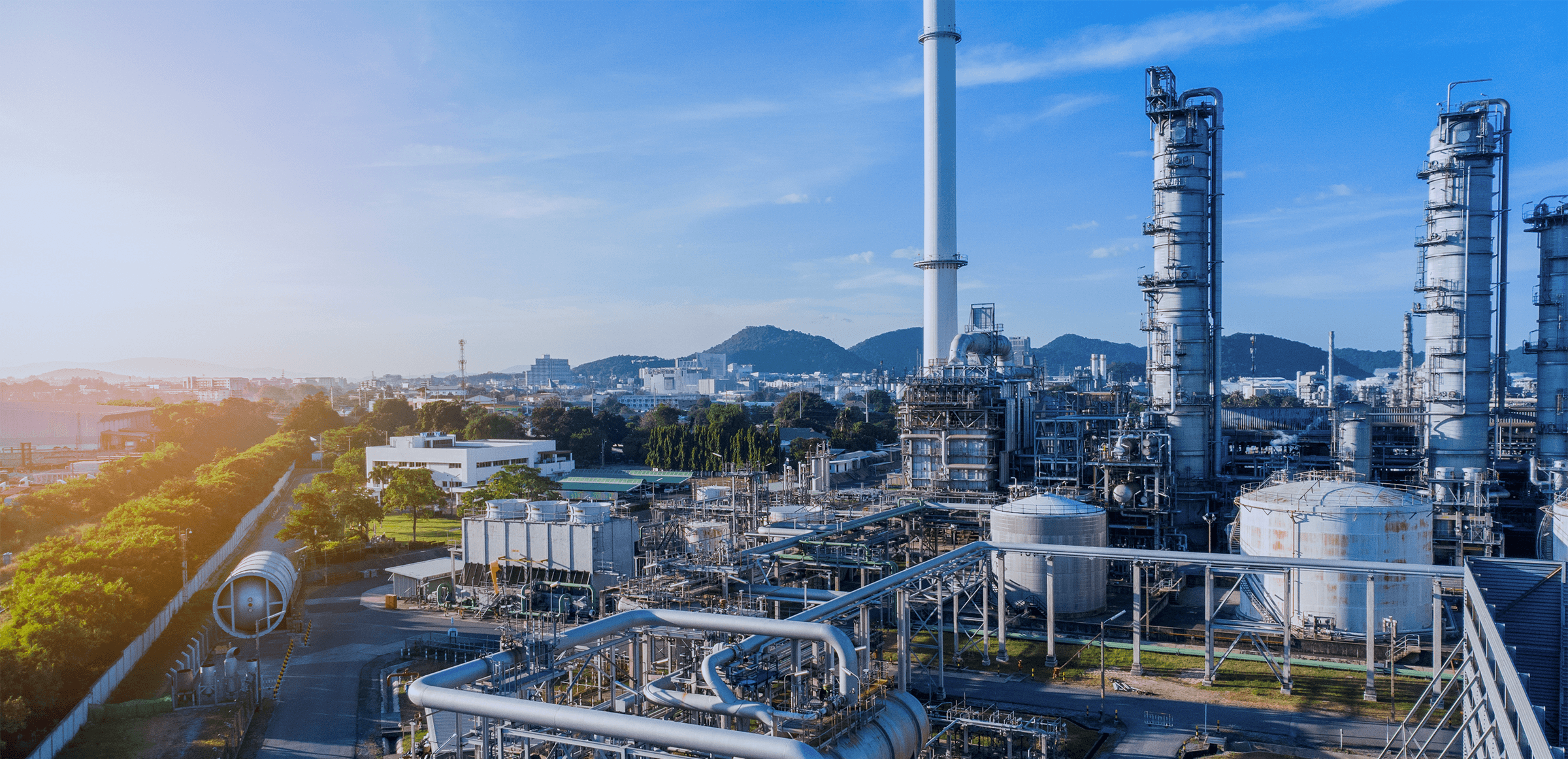

Process heating is critical to a variety of industrial processes, from food manufacturing to pollution control systems. Indirect-fired heaters heat air for applications where direct contact with combustion products is detrimental to the process or product. Unlike direct heaters, indirect-fired heaters heat process air without contaminating the product with combustion products.

Like a boiler, indirect-fire air heaters create energy by combusting liquid or gaseous fuel in a combustion chamber. The resulting combustion products heat the process air to the desired temperature but are kept separate from the process air by an air-to-air heat exchanger.

Purpose of Indirect-Fired Air Heaters

Single Hot Pass Design

This indirect-fired heater design uses a burner and high-temperature chamber to heat process air as it passes over the heater. Heat is generated by a burner firing into a specially designed high-temperature chamber, which is engineered to radiate. The process air is pulled, or blown, over the heater and heated to the desired temperature. This system is ideal for recirculated air processes like paint booths and smokers. This type of indirect-fired heater is approximately 60-70% efficient.

Multiple Hot Pass Design

These indirect-fired heaters consist of a burner, a combustion chamber, an air-to-air heat exchanger, and high-temperature fans. In this type of heater, the high-temperature fans pull the hot products of combustion, produced by the burner, through an air-to-air heat exchanger heating the process air passing through the other side of the heat exchanger. The hot gasses then reenter the system to create a continuous heating loop. As the process air is separated from the hot gases by the heat exchanger, they are free from products of combustion providing hot, clean air to the process.

This design can heat high volumes of air with more than 90% efficiency. The heater’s efficiency can be further enhanced by installing an air-to-air heat exchanger in the process exhaust system, so clean air can be heated before it enters the main heating chamber. This type of heater is ideal for use in food-grade spray dryers and mineral drying applications.

Applications of Indirect-Fired Air Heaters

Indirect-fired heaters are valued for their ability to rapidly and efficiently heat process air without contaminating processes through direct contact or the diffusion of combustion byproducts into the process. Applications that benefit from indirect fire heaters include:

- Food Manufacturing: Perfect for food-grade applications such as spray dryers for dairy products, produce, and other food products.

- Pharmaceuticals: Incorporated into pharmaceutical manufacturing for heating and drying products.

- Chemical Manufacturing: Used to heat and dry chemicals while preventing the intrusion of contaminants from combustion processes.

- Automotive Paint and Detailing: Used in recirculating systems for painting, lining, coating, and detailing.

- Pollution Control Systems: Heats downstream exhaust to eliminate pollutants without adding additional contaminants to the stream.

- Iron Industry: Used to heat pellets and other products without introducing contaminants that can cause unwanted chemical impurities.

- Printing Presses: Used to quickly and efficiently dry ink on paper products, labels, and other high-volume products.

- Heating Industrial and Commercial Buildings: Ensures clean heated air is circulated in commercial and industrial facilities for a healthier work environment.

Direct vs. Indirect Air Heaters

While direct-air heating is the most common method of industrial heating, it does introduce products of combustion into the process air stream. In applications where the product cannot be exposed to the CO2, CO, NOx, H2O, SOx, or particulate produced during the combustion process, an indirect air heater is the only option.

Cutting-Edge Air-to-Air Heating Solutions by PRE-heat, Inc.

PRE-heat, Inc., is a leading provider of air-to-air indirect heating solutions for our customers in commercial and industrial sectors. As experienced fired-heater manufacturers, we leverage our expertise to create economical, efficient, and effective solutions to meet a variety of process heating needs. To learn more about our extensive selection of indirect-fired heaters and custom heating solutions, contact our experts today or request a quote.

For more than 40 years, the team at PRE-heat, Inc. has focused on high-performance industrial air-to-air heat exchangers as well Read more

Every facility loses heat to the atmosphere. In industrial settings, this loss is a significant source of wasted energy and Read more

Air-to-air heat exchangers are common in various industries, effectively carrying out heat transfer and recovering wasted heat from exhaust air Read more

Many industrial processes create heated air as some type of exhaust or byproduct. Typically, this heated air gets vented outside Read more

- Published in Air to Air Heat Exchangers, Featured

How Do Shell & Tube Heat Exchangers Work?

For more than 40 years, the team at PRE-heat, Inc. has focused on high-performance industrial air-to-air heat exchangers as well as packaged heat recovery systems, with a specialization in customized builds and designs. Shell and tube heat exchangers, part of PRE-heat’s extensive product line, are available in several options to effectively carry out heat transfer. Learn more about what these heat exchangers do and how they do it.

What Is the Purpose of Shell & Tube Heat Exchangers?

Shell and tube heat exchangers recover energy from the heat of equipment like furnaces, ovens, kilns, and dryers. They also serve as primary and secondary systems for heat recovery with volatile organic compound (VOC) abatement systems or fume incinerators. In furnaces, properly functioning heat exchangers prevent unsuccessful fuel combustion, which would lead to harmful levels of carbon monoxide in the air. They’re also helpful in industries like pharmaceuticals, food and beverage, and petrochemical for offering thermal control in things like tank heaters, condensers, process coolers, and more.

Among their strengths is the fact that their design allows them to accommodate higher levels of pressure as well as extreme temperatures, particularly as compared to other varieties like plate and wheel exchangers. They also maintain reliable performance in environments that might challenge other systems, such as locations with high volumes of dust in the air. These heat exchangers are easy to clean and maintain, all while providing superior thermal transfer.

Types of Shell & Tube Heat Exchangers

It is typically simple to build various tubular heat exchanger subtypes because of the versatility of available shell, tube, and front and rear header arrangements, making these exchangers a common choice for design engineers in the process industry. Some exchanger options include:

Fixed tube sheet exchanger.

The economical structural design of this exchanger is simplistic with the tube sheet fused to its shell. This makes chemical or mechanical cleaning of the tubes possible, though the external surface of the tube is inaccessible for all except chemical cleanings.

Free Floating Tube heat exchanger

Unlike the design of fixed tube sheet exchangers, Free Floating Tube heat exchangers are structured so that each tube within the exchanger can grow separately from the rest.

U-tube heat exchanger

The U-tube design in this exchanger enables limitless thermal expansion. The tube is straightened or bent into a U configuration, hence the name. The front header can have any design, but the rear header is M-shaped. Cleaning can be challenging, so these heat exchangers are ideal for tasks with clean tube-side fluid. Like floating heat exchangers, U-tube heat exchangers have the option for removable bundles.

How Do Heat Exchangers Work?

Shell and tube heat exchangers are made up of a metal enclosure, or shell, acting as a pressure vessel with hollow, bundled metal tubing passing through it as part of a compact design. They work by transferring heat safely from point A to point B. To achieve this, they utilize thermal exchange and transmit warmth between two working media like liquids, gases, or a combination of both through tubes installed in the cylindrical case. The temperatures of the two materials are different than each other, and this variation is what drives the transfer of heat.

Using furnaces as an example, while burning propane fuel or natural gas, a furnace exhaust’s by-product, or its flue gas, passes through the heat exchanger. Since the flue gas is hot, it warms the metal as it moves through the system and, ultimately, a furnace’s exhaust outlet. While this is occurring, the metal’s heat warms the air surrounding the heat exchanger’s exterior surface. In high-efficiency furnaces, there will also be a secondary heat exchanger, in which the heat from the flue gas helps to generate water vapor which is a catalyst for greater latent heat release. This will make the furnace more efficient.

Shell & Tube Heat Exchangers From PRE-heat

Among its many offerings, PRE-heat’s product line includes our rugged air-to-air industrial shell and tube ALT-imate heat exchanger for excessive temperatures and dirty exhaust air streams as primary and secondary heat exchangers. In vertical or horizontal options and a variety of other configurations, they have applications in furnaces, ovens, kilns, and dryers of virtually all kinds.

Our company uses square, triangular, and rotated square and triangular tube patterns, among others. With partial or full baffles, we also utilize multiple shell side flow and tube side passes. This gives our team the flexibility to custom design an exchanger for your specific space and performance needs. PRE-heat’s quality systems can withstand temperatures and air pressures of as much as 1,800° F and 25 psi, respectively.

Contact us today or request a quote to learn more about how the PRE-heat team can develop and construct a shell-and-tube heat exchanger that complies with your unique specifications.

Process heating is critical to a variety of industrial processes, from food manufacturing to pollution control systems. Indirect-fired heaters heat Read more

Every facility loses heat to the atmosphere. In industrial settings, this loss is a significant source of wasted energy and Read more

Air-to-air heat exchangers are common in various industries, effectively carrying out heat transfer and recovering wasted heat from exhaust air Read more

Many industrial processes create heated air as some type of exhaust or byproduct. Typically, this heated air gets vented outside Read more

- Published in Air to Air Heat Exchangers, Featured

- 1

- 2

FAQ

Find quick answers to the questions you may have about PRE-heat's air-to-air products and services.

Resources

Find industry resources along with trends and opportunities to download supporting air-to-air documents.

Contact Us

Contact our team with any additional questions you may have or if you are interested in heat exchanger solutions.

newsletter

EXPLORE

SUPPORT

Copyright © 2025 Pre-Heat Inc. All Rights Reserved.