Air-to-Air Cooling Tower Heat Exchangers

Trusted industrial air recovery

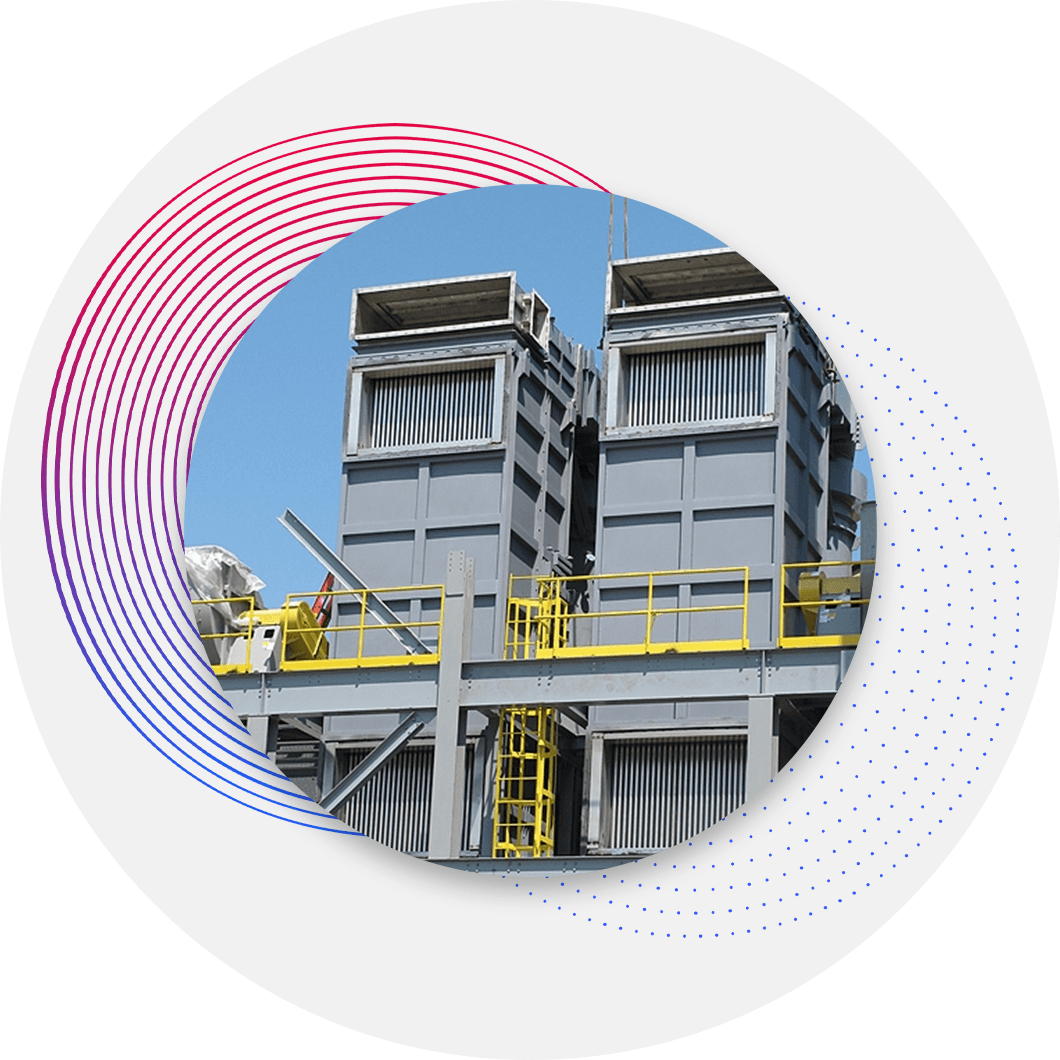

PRE-heat's vertical shell and tube heat exchanger with larger tube diameters are designed for cooling air streams with large amounts of particulates before it enters a bag house for final cleaning and discharge into the atmosphere. Hot, dirty air enters the top of the unit and goes down through the tubes. Most of the particulates fall through the tubes and are collected underneath the exchanger in a large material collection hopper.

Recapture

PRE-heat industrial air-to-air technology captures exhaust heat waste.

Reheat

The air is then reheated through a low-energy efficient process.

Recycle

Heated air is reused across various applications, saving the environment and money.

Size

Large

Temperature

Up to 1600ºF

Pressure

Various

Effectiveness

Up to 75%

Flow Ratio

Approx. 5:1

Lifespan

15-20 Years

Corrosion Resistance

![]()

Dust Handling

![]()

Cleaning

![]()

Applications

Any oven, dryer, kiln cupola or incinerator with a particulate exhaust emission that needs to be cooled, or dried out before going into a more stringent, temperature-sensitive, particulate collection device

Food & Feed Dryers

Mineral Dryers

Silicone Thermal Incinerators

Solid Waste Incinerators

All types of Metal Chip Dryers & Incinerators

High-Temperature Kilns for Curing Materials

Tower Systems

Vertical shell and tube heat exchangers with larger tube diameters are designed to cool air streams with large amounts of particulates before they enter a baghouse for final cleaning and discharge into

the atmosphere. This system allows particulates to fall underneath the exchanger, making cleaning easier.

Cleaning Design

The cooling towers' design is to handle dirty air and be easily cleaned. To completely clean the tubes, it’s usually as simple as running a brush, high-pressure air, water, or steam down through the tube. Our cooling towers are also equipped with access doors. Cooling the air stream reduces the size of the baghouse, limits the possibility of fires, and allows operators to use lower-temperature, more cost-effective bags.

Tower Applications

Our air-to-air cooling tower heat exchangers are commonly seen in industries that incorporate dryers, incinerators, and any oven, dryer, kiln cupola, or incinerator with a particulate exhaust emission that needs to be cooled or dried out before going into a more stringent, temperature sensitive, particulate collection device.

Technical Experts

PRE-heat is best known for our innovative, customizable heat exchange and recovery systems. Our systems are durable and robust, featuring all-metal, all-welded construction with variable arrangements and thickness.

Huge Energy Savings

Dive into the following examples to help visualize your ROI timeline.

Example 1: Dimple Plate, Spray Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 2: Dimple Plate, Electric Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 3: Dimple Plate, Industrial Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 4: Dimple Plate, Combustion Air Preheater

ROI: 1.1 YearsExample 5: Cooling Tower, Bag House Cooler & Waste Heat Recovery

ROI: 1.1 YearsExample 6: Tubular, Thermal Oxidizer Fume Preheater

ROI: 1.1 YearsFeatured Case Studies

View our case studies and learn how we support businesses through custom solutions and engineering, as well as examples of problems we have taken on and solved.

FAQ

Find quick answers to the questions you may have about PRE-heat's air-to-air products and services.

Resources

Find industry resources along with trends and opportunities to download supporting air-to-air documents.

Contact Us

Contact our team with any additional questions you may have or if you are interested in heat exchanger solutions.

newsletter

EXPLORE

SUPPORT

Copyright © 2025 Pre-Heat Inc. All Rights Reserved.