Air-to-Air Dimple Plate Heat Exchangers

Leading air recovery technology

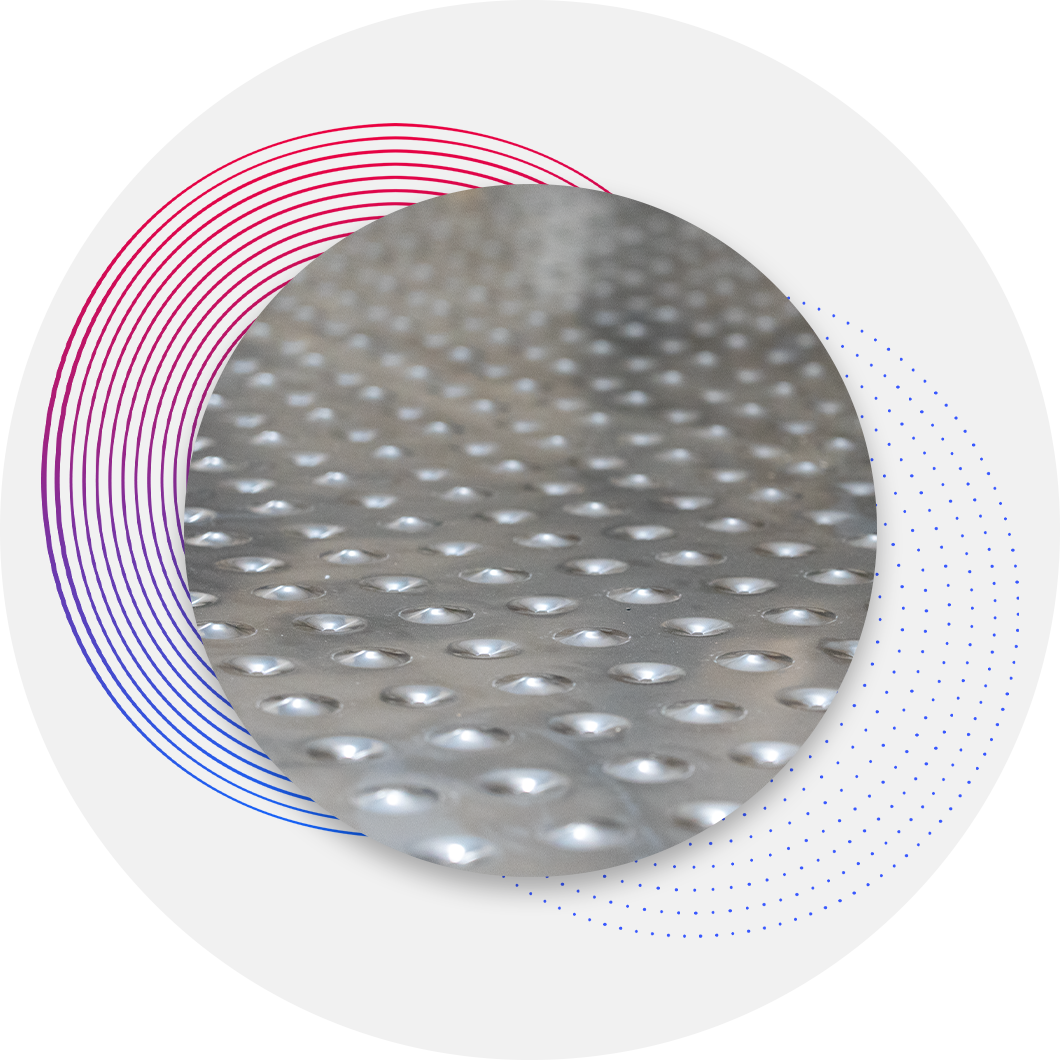

PRE-heat air-to-air dimple plate (DPL) heat exchangers have many consistently spaced dimples, which are ideal for bettering turbulence and managing low-pressure drops. The DPL unit is our most versatile, rugged, heavy-duty, yet cleanable plate heat exchanger. The DPL utilizes dimples on each plate to maintain plate spacing and enhance turbulence while operating at lower pressure drops. Our DPL is an all-welded plate-type heat exchanger with the most robust primary seal weld in the industry.

Recapture

PRE-heat industrial air-to-air technology captures exhaust heat waste.

Reheat

The air is then reheated through a low-energy efficient process.

Recycle

Heated air is reused across various applications, saving the environment and money.

Size

Compact

Temperature

Up to 1500ºF

Pressure

Up To 3 PSI

Effectiveness

Up to 85%

Flow Ratio

Approx. 3:1

Lifespan

20+ Years

Corrosion Resistance

![]()

Dust Handling

![]()

Cleaning

![]()

Dimple Plate Technology

The dimple plate heat exchanger is versatile, rugged, and heavy-duty,

yet cleanable. Variable plate thickness, plate spacing, plate sizes,

and air-flow patterns are designed to meet system requirements and

fine-tune the system to maximize efficiency and cost.

Product Applications

Our dimple plate heat exchangers are commonly seen in industries that incorporate chemical processing, food processing, automotive heater boxes, and furnaces. They can also be implemented in environments with corrosive atmospheres, wide temperature variations, high temperatures, and dusty air streams.

Exchanger Design

For low-temperature systems, aluminized steel or 409 stainless steel may be used. For corrosive or high-temperature applications, various grades of stainless steel alloys are used. Standard materials are 304, 326, 309, and 310 stainless steels.

Technical Experts

PRE-heat is best known for our innovative, customizable heat exchange and recovery systems. Our systems are durable and robust, featuring all-metal, all-welded construction with variable arrangements and thickness.

Applications

Air pollution control systems, primary and secondary energy recovery

Furnace

Plastics industry, pellet pre-heating

Plastics, painted parts drying oven

Solvent recovery systems, pre-cooler/re-heater

Automotive, e-coat and paint curing ovens

Bakery oven pre-heater

Power generation, pre-heating of jet engine inlet air

Printing industry, web drying oven pre-heater

Mineral industry drying systems for raw minerals curing

Engine manufacturing, engine test cell heat recovery

Tape manufacturing, indirect heating of oven zones

Bottling plant, indirect heating of sterilized air used for drying of bottles

Asphalt plant, pre-heater

Make up air/heat recovery systems

Paper machine hood exhaust

Textile, tenter frame – heat set, dye set pre-heaters

Grain dryers, indirect heating

Ground water remediation system, fume pre-heater

Machining plant, parts washers

Batch oven air pre-heating

Kiln exhaust cooling before bag-house

Furniture manufacturing, paint, stain and coating

Features

All-metal, all-welded construction

Robust primary seal welds

High-efficiency heat transfer in a compact design

High-temperature designs

Stainless steel alloys

Airflow patterns to maximize each application

100 CFM to 100,000 CFM

Variable plate spacing

Variable plate thickness

Vertical or horizontal units

Cleanable units for dirty applications

Options

Access doors for cleaning and inspection

Insulation and cladding

By-pass ductwork with dampers and controls

Transitions, plenums, filtered intakes and structural steel support systems

Huge Energy Savings

Dive into the following examples to help visualize your ROI timeline.

Example 1: Dimple Plate, Spray Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 2: Dimple Plate, Electric Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 3: Dimple Plate, Industrial Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 4: Dimple Plate, Combustion Air Preheater

ROI: 1.1 YearsExample 5: Cooling Tower, Bag House Cooler & Waste Heat Recovery

ROI: 1.1 YearsExample 6: Tubular, Thermal Oxidizer Fume Preheater

ROI: 1.1 YearsFeatured Case Studies

View our case studies and learn how we support businesses through custom solutions and engineering, as well as examples of problems we have taken on and solved.

FAQ

Find quick answers to the questions you may have about PRE-heat's air-to-air products and services.

Resources

Find industry resources along with trends and opportunities to download supporting air-to-air documents.

Contact Us

Contact our team with any additional questions you may have or if you are interested in heat exchanger solutions.

newsletter

EXPLORE

SUPPORT

Copyright © 2025 Pre-Heat Inc. All Rights Reserved.