Air-to-Air Shell and Tube Heat Exchangers

Durable air-to-air efficiency

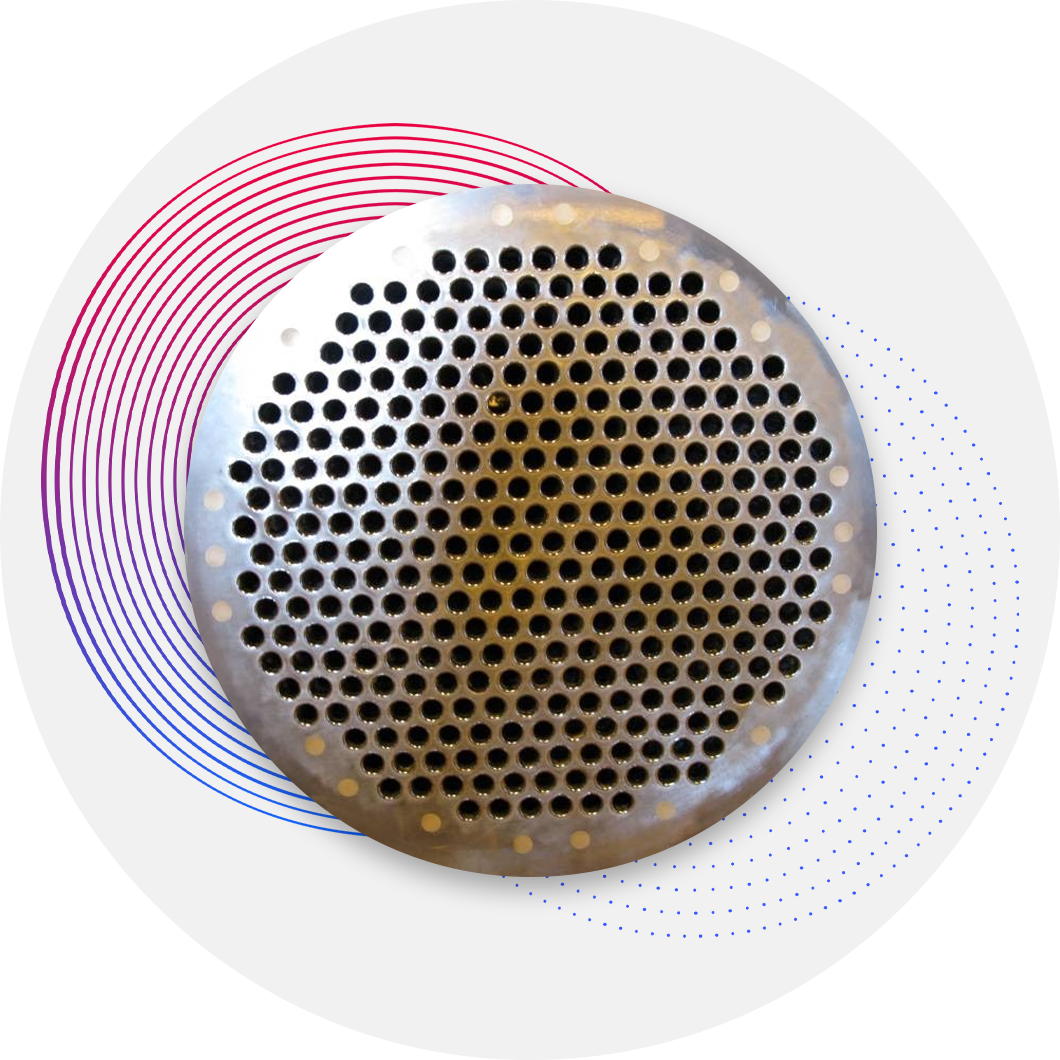

Our heavy-duty, most robust heat exchanger for very high temperatures and very dirty exhaust air streams, where a plate heat exchanger just will not work. PRE-heat, Inc. manufactures a wide variety of industrial, air-to-air, shell and tube heat exchangers.

Our high-quality, rugged shell and tube heat exchangers are used as primary and secondary heat exchangers on all types of VOC abatement or fume incineration, including catalytic, thermal recuperative, and thermal regenerative incinerators. They are also used to recover valuable heat energy from industrial furnaces, kilns, ovens, and dryers of all types.

Recapture

PRE-heat industrial air-to-air technology captures exhaust heat waste.

Reheat

The air is then reheated through a low-energy efficient process.

Recycle

Heated air is reused across various applications, saving the environment and money.

Size

Large

Temperature

Up to 1600ºF

Pressure

Up to 7 PSI

Effectiveness

Up to 75%

Flow Ratio

Approx. 5:1

Lifespan

15-20 Years

Corrosion Resistance

![]()

Dust Handling

![]()

Cleaning

![]()

Airlock Design

Our systems use a proprietary airlock floating tube expansion design to eliminate the destructive forces caused by uneven growth from partial heat exchanger plugging. This alone dramatically increases the lifecycles of our heat exchangers.

Versatility & Sustainability

PRE-heat can use in-line and staggered tube patterns, as well as multiple shell side flow passes and multiple tube side passes, with full or partial baffles. This allows us to design the proper exchanger to meet your performance needs and fit into the space required.

Tube Applications

Our air-to-air shell and tube designs are commonly seen in industries

with high temperatures and very dirty exhaust air streams. They

can be utilized in heat exchangers for all types of VOC abatement for fume incineration. They can also recover heat energy from

industrial furnaces, kilns, ovens, and dryers of all types.

Technical Experts

PRE-heat is best known for our innovative, customizable heat exchange and recovery systems. Our systems are durable and robust, featuring all-metal, all-welded construction with variable arrangements and thickness.

Casing Shape

Rectangular

Round

Oblong

Square

Elliptical

Orientation

Vertical

Horizontal

Casing Material

Mild Steel (Primed and Painted)

Stainless Steel (304, 316)

Ceramic Fiber

4 to 8 in

Outside Casings

7 Ga. To .375 in

Insulation

Internal

Tube Type

Welded

Seamless

Tube Outside Diameter (OD)

.5 to 4 in

Tube Thickness (Wall)

.049 to .125 in

Tube Length

2 to 40 ft.

Tube Material

Mild Steel

Stainless Steel (304, 316L, 309, 310, 321, 409)

Alloy 20

Titanium

Other Exotic Metals

Tube Layout

In-Line

Staggered

Baffle Design

Full

Partial

Configuration

Cross Flow

Multiple Shell Pass

Multiple Tube Pass

Full Passes with External Turns

Partial Passes with Internal Turns

Expansion Systems

Air Lock: Tubes Expand and Contract Freely and Individually

Bellows System

No Cross Contamination

Air Flow

100 to 100,000 CFM

Pressure

Up to 5 psi

Temperature

Up to 1800 F

Environment

Corrosive

Contaminations

Particulates

- Silicone

- Sand

Options

Access Doors

Hot Gas By-Pass Damper

By-Pass Ductwork with Dampers and Controls

Transitions

Plenums

Filtered Intakes

Structural Steel Support Systems

Automatic Wash System

Castable Refractories

Companion Flange Sets

Expansion Joints

Industrial Walkways and Ladders

Externally Insulated

Internally Insulated

Testing

Pressure

Dye Penetrants

Huge Energy Savings

Dive into the following examples to help visualize your ROI timeline.

Example 1: Dimple Plate, Spray Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 2: Dimple Plate, Electric Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 3: Dimple Plate, Industrial Dryer Waste Heat Recovery

ROI: 1.1 YearsExample 4: Dimple Plate, Combustion Air Preheater

ROI: 1.1 YearsExample 5: Cooling Tower, Bag House Cooler & Waste Heat Recovery

ROI: 1.1 YearsExample 6: Tubular, Thermal Oxidizer Fume Preheater

ROI: 1.1 YearsFeatured Case Studies

View our case studies and learn how we support businesses through custom solutions and engineering.

FAQ

Find quick answers to the questions you may have about PRE-heat's air-to-air products and services.

Resources

Find industry resources along with trends and opportunities to download supporting air-to-air documents.

Contact Us

Contact our team with any additional questions you may have or if you are interested in heat exchanger solutions.

newsletter

EXPLORE

SUPPORT

Copyright © 2025 Pre-Heat Inc. All Rights Reserved.